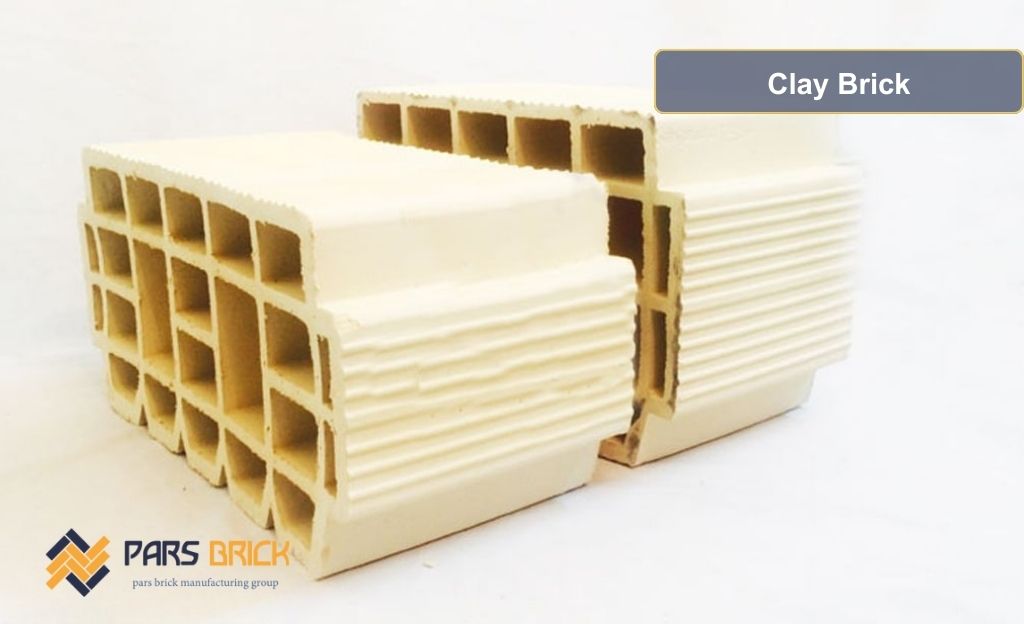

Types of Pottery Bricks

Pottery bricks, also known as terracotta bricks, come in various types and styles, each tailored to specific architectural and construction needs. These bricks are made from fired clay and are known for their durability, versatility, and aesthetic appeal in both traditional and modern architecture.

Getting to Know Pottery Bricks Better

Pottery bricks are among the oldest building materials, with some archaeologists estimating their origin to be around 10,000 years ago. In Iran, remnants of kilns used for firing pottery have been discovered in Susa and Sialk, Kashan, dating back to the 4th millennium BCE. Additionally, evidence of the production and use of pottery bricks has been found in India, suggesting a history of 6,000 years for this material in that region. The word safal (clay) has Babylonian origins and referred to mud bricks upon which inscriptions, laws, and similar texts were written. It is believed that the technique of firing clay was first discovered when the walls and floors of hearths made from clay were accidentally hardened by fire.

For more information, feel free to check out our Brick facade

Learn More About the Firing Process of Bricks

The early kilns used for firing pottery bricks likely consisted of alternating layers of firewood and unfired bricks stacked on top of each other. The technique of using pottery bricks spread from West Asia to Egypt, then to Rome, and further east to India and China. In the 4th century, Europeans began using this type of brick, although its popularity eventually waned. However, clay bricks experienced a revival in the 12th century, starting in Italy.In ancient Iran, large and magnificent structures were built using clay bricks, some of which have withstood the test of time and remain standing to this day. Examples include:

- The Taq Kasra in the Western Region of Ancient Iran

-

The Mausoleum of Shah Ismail Samanid in Gonbad-e Kavus

-

The Mosque of Isfahan

The Stages of Pottery Brick Production:

- Excavation and Extraction of Raw Materials

- Preparation of Raw Materials

- Molding

- Drying

- Unloading and Storing the Product

- Types of Kilns for Firing Clay Bricks

After the bricks are dried, they are stacked in the kiln in such a way that there are gaps between them, allowing the hot gases and flames to pass through efficiently.

For more information, feel free to check out our traditional brick

Types of Kilns for Firing Pottery Bricks:

- Vertical Shaft Kiln (Tanuri Kiln)

- Hoffman Kiln

- Tunnel Kiln

Tunnel kilns are the most modern type of brick-firing kilns. They are also used for firing high-quality ceramic tiles and industrial ceramics.

Characteristics of Quality Pottery Bricks:

A good clay brick should produce a ringing sound when struck against another brick. This ringing sound indicates the brick’s density, strength, and low water absorption. A good clay brick should also meet the following criteria:

- Fire Resistance: It should not melt or deform under intense heat.

- Uniform Color: The color of the brick should be consistent and even across its surface.

- Smooth Surface: Its surface should be free of holes and imperfections.

- Hardness: The brick should be hard enough that it cannot be scratched with a fingernail.

Learn More About Calculating the Number of Bricks Needed for a Building

For more information on how to calculate the required number of bricks for construction, click here.