Everything You Need to Know About Refractory Facing Brick

Refractory facing brick is a type of brick made from fireclay and refractory materials. It is manufactured with a dense and fine molecular structure at extremely high temperatures exceeding 1500°C. As its name suggests, this brick is highly heat-resistant and is widely used in kilns, furnaces, ladles, and industrial insulation.Refractory facing bricks are produced using fire-resistant clay. Due to their variety of colors and unique beauty, they are also commonly used in building façades.Some of the well-known varieties include the English-style red brick and Shamotte brick.

For more information, feel free to check out our refractory bricks (fire brick)

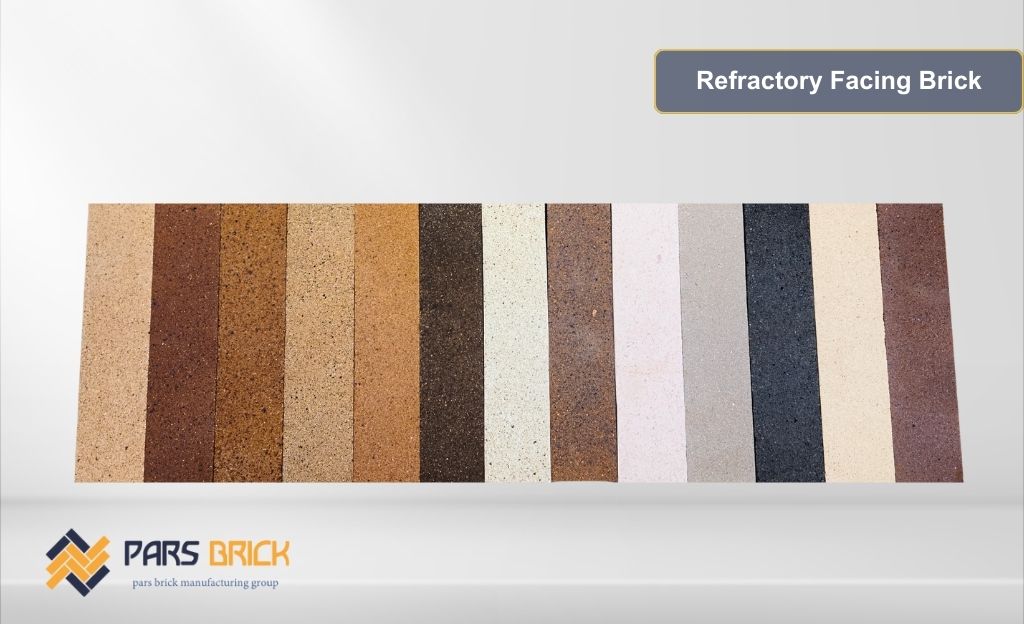

Refractory Facing Brick

Refractory facing bricks come in a wide variety of colors, ranging from black to white and beyond. The price of refractory facing bricks is higher compared to other types of facing bricks. This is due to the high cost of fire-resistant clay and the more complex production process compared to other bricks.Building with refractory bricks has a unique appeal, and today, their numerous advantages have made them a popular choice among architects and engineers for creating the most beautiful building façades.Refractory bricks are made from fire-resistant clay and kaolin (a type of Chinese clay), which have a finer and denser structure compared to other bricks. Interestingly, when constructing façades with refractory facing bricks, greater artistry and precision are required. This very characteristic adds to the charm and superiority of refractory brick façades. Therefore, it is highly recommended to use skilled, experienced installers who are proficient in the proper installation and grouting of refractory bricks.

Variety in Refractory Facing Bricks

Refractory facing bricks come in a wide range of colors, sizes, and designs. Many creative designers use these bricks randomly during façade construction, which not only enhances the beauty and elegance of the façade but also highlights the diversity in style, design, and color of each individual brick. Due to their high durability, optimal water absorption, and strong adhesion when in contact with mortar, refractory bricks offer distinct advantages over other materials during installation and execution.Today, the use of refractory bricks ensures exceptional quality and durability in brick façades.From ancient times to the present day, building façades have carried the dual responsibility of resistance and protection.

Architects must exercise great care in selecting high-quality and durable materials to protect brick façades from various environmental and climatic factors. Constructing buildings with brick façades that remain strong and resilient against wind, rain, heat, and cold is no easy task. In today’s world, the demand for durable and professional façades is a top priority for cities across the globe.

For more information, feel free to check out our Black refractory Brick

Using Refractory Bricks in Building Façades

In addition to heat resistance, compressive strength, lasting quality, durability, and flexibility in various climatic conditions are among the key factors that have made refractory bricks a popular choice for building façades. When refractory bricks are made with a standard formulation, you can rest assured that the building façade will remain attractive and as pristine as the first day for many years. Adhering to standards for color stability and efflorescence resistance during the production of refractory bricks ensures long-term quality. Even years after installation, there will be no discoloration, deformation, algae growth, or efflorescence on the surface.Façade design in buildings is an expression of identity and culture.Just as clothing represents a person’s character, the façade of a building reflects the owner’s identity, the property’s location, and its intended use.By observing façades made with refractory bricks, one can recognize their superiority and distinctive features, which stem from the wide variety of colors and designs available. The color of refractory bricks is intrinsic to their material, which is one of the reasons why façades made with refractory bricks appear so unique and captivating. You could look at a building façade made with refractory bricks for hours without your eyes feeling tired.Today, refractory facing bricks are widely used to protect and preserve buildings against abrasion, repeated frost, and to ensure compatibility with all climatic conditions.

For more information, feel free to check out our Gray refractory brick facade

Creating Façades with Refractory Bricks

Using refractory bricks in façade design is considered a hallmark of postmodern architecture.In addition to their aesthetic applications, refractory bricks are widely used in the inner linings of industrial furnaces due to their high resistance to heat. These bricks come in various types, and depending on the raw materials used in their composition, they can withstand a wide range of temperatures. Until the 1960s, carbon and fireclay were commonly used for furnace linings, but today, with the development of different types of refractory bricks, they have become the preferred material for this purpose.Refractory facing bricks are available in a variety of colors and designs, making them highly appealing to architects and engineers.Refractory bricks that incorporate specific elements such as AL₂O₃ (alumina) and SiO₂ (silica) in their raw materials undergo firing at high temperatures, resulting in a final product with exceptional density and durability compared to other facing bricks. These bricks remain unchanged under all climatic conditions and are resistant to temperature and humidity fluctuations. Additionally, they have a significantly longer lifespan and are far more resistant to wear and erosion, making them tens of times more durable than ordinary bricks.

For more information, feel free to check out our Firebrick paving

How to Identify Refractory Bricks

Refractory bricks can be easily identified by their appearance. Their surface is rougher, coarser, and free of excess dust compared to other types of bricks. Additionally, refractory bricks often feature fine, colorful granules on their surface. It is important to note that when you use standard-compliant refractory bricks, your building façade will remain intact for years without any decay or erosion. Over time, these bricks do not lose their color, develop efflorescence, or experience surface wear.The kilns used to fire refractory bricks are either tunnel kilns or shuttle kilns. In tunnel kilns, heat is not distributed evenly, which can result in bricks of varying quality and random characteristics. Sometimes, excessive heat in certain parts of the kiln causes bricks in those areas to warp, leading to non-standard sizes, which are often smaller than the usual dimensions.Important Note:

If the production process uses a tunnel kiln with uniform heat distribution across all sections, the resulting bricks will have consistent colors within the same spectrum, and no size variations will be observed. Refractory bricks fired in tunnel kilns exhibit higher strength and meet stricter environmental standards compared to those fired in shuttle kilns.

Tips for Grouting Refractory Bricks

- Moisten the connection area before installing refractory bricks.

- The thickness of the mortar behind the bricks should be between 2 to 4 centimeters.

- The ideal temperature for installing refractory bricks is between 5°C and 35°C.

- Avoid façade work during frosty weather whenever possible.

- Do not use any organic materials in the sand or water used for the mortar.

- The most suitable time for grouting is at least a few weeks after the bricks have been installed.

- Moisten the grouting area before starting the process.

- The prepared mortar for grouting should be used within 2 to 3 hours.

- Knead the grouting mortar for a few minutes to ensure it is well-mixed and homogeneous.

- Avoid using a mortar board for grouting.

- Place the mortar on the grouting tool and then apply it between the grooves of two bricks.

- Do not use a wet cloth to clean excess mortar from the grooves.

- Use a brush to clean off excess mortar from the grooves 2 hours after application.

- Once the structure is completely dry, apply a resin coating to waterproof the bricks.

For more information, feel free to check out our White refractory brick facade

Why Refractory Brick Façades Are Superior

- High quality and durability

- Optimal water absorption

- Manufactured in precisely engineered dimensions for any type of design

- Ability to produce in various sizes (based on style and customer orders)

- Popular and aesthetically pleasing

- Natural, fade-resistant colors that do not change under sunlight

- Made from natural and premium raw materials

- Resistant to abrasion, scratches, and scuffs

- Resistant to acids and bases

- Acts as an insulator against both heat and cold

- Resistant to freezing and harsh weather conditions

- Resistant to fire and natural elements

- Available in a wide range of colors

- Environmentally friendly

- Maintains optimal water absorption levels

Refractory brick façades combine beauty, functionality, and durability, making them a top choice for architects and designers worldwide.

Early Examples of Brickwork

One of the earliest examples of brickwork in Rome is the reconstruction of the Pantheon, featuring an exemplary brick dome. Another significant example is the Baths of Hadrian, where terracotta columns were used to reinforce surfaces exposed to high heat, all constructed with brick.In Western Europe, brick has become one of the most widely used architectural materials in the world, a trend that continues to this day. This widespread adoption was largely driven by the need to combat the devastating fires that frequently occurred.After the Great Fire of 1666, London transformed from a city built predominantly of wood into a city of brick. Refractory bricks, in particular, were employed as a protective measure against future fires.